Cherry Point Hardwood Floors loves Bona’s Super Sport One Finish

Cherry Point Hardwood Floors recently completed a squash court at a private residence in the Victoria area using Bona’s Super Sport One finish. Looks great Nick!

Cherry Point Hardwood Floors recently completed a squash court at a private residence in the Victoria area using Bona’s Super Sport One finish. Looks great Nick!

On Monday, November 2, 2015 we’ll be at our new larger location:

612 GARBALLY ROAD VICTORIA, V8T 2K2

Duraseal Masterline Polyurethane $6.99 / Quart

A transparent, tough, oil-based finish formulated to provide excellent durability and remarkable

stain resistance. DuraSeal® Masterline Polyurethane gives wood floors depth and richness while

protecting them from dirt and spills.

Available in satin and semi-gloss sheens.

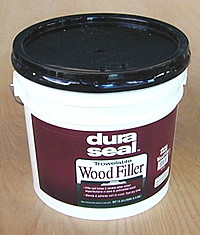

Duraseal Red Oak Full Trowel Wood Filler

$69.95 / 3.5 Gal Pail

A safe, non-flammable, water based product for use across an entire wood floor.

This product fills nail holes and covers other minor imperfections in bare and unfinished wood.

It has a fast dry time, blends and adheres well to wood, sands easily and absorbs stain similarly to wood.

4 ½” X 5 ½” Sponges $19.95 Box of 20

Available in: Fine, Extrafine, Superfine and Microfine

COLUMBIA PAINTS & INDUSTRIAL SUPPLIES

Bona Woodline Polyurethane

Bona Woodline Polyurethane is a premium, oil-modified wood floor finish formulated for interior use on residential and commercial wood floors. Woodline provides a tough, protective coat and it’s slight amber color enhances natural color of wood. Gloss, Semi-Gloss or Satin Sheens. Full cases only. No Enviro Fees

Duraseal Masterline Polyurethane

A transparent, tough, oil-based finish formulated to provide excellent durability and remarkable stain resistance. DuraSeal® Masterline Polyurethane gives wood floors depth and richness while protecting them from dirt and spills. Available in a satin sheen.

Basic Coatings Basic 1 Waterbased Floor Finish

Economical Waterbased Floor Finish

Basic Coatings Emulsion PRO Waterbased Floor Finish

New PRO Advanced Oil and Water Wood Floor Finish and Sealer As a breakthrough in value, Emulsion PRO has what so many waterbased coatings don’t – the warm, rich, amber tones of an oil-based finish. Emulsion PRO™ is self-sealing, VOC compliant and has an oxidative cross-linked urethane system that produces better wear properties than traditional oil finishes.

Bona Novia Waterbased Floor Finish

Unsurpassed flow and leveling, defoaming, and numerous application options make Bona Novia the easiest to use waterborne finish on the market. When Bona Novia is used with Bona AmberSeal, it is a budget sensitive, dependable alternative to any oil-based system. GREENGUARD certified for indoor air quality.

* Prices subject to change with out notice. All prices quoted are F.O.B. Victoria, B.C. Canada

“Bona Bits”

Application Problems When Finishing Floors

Slow Drying. Most finishes dry slowly during perioids of high humididty (over 70%) and/or temperatures below 15C. Working in totally enclosed areas keeps solvents or water contained and will cause slow drying in solvent-based finishes and slow drying plus severe grain raising in water-based finishes. Increasing heat or air circulation helps in these situations.

Fast Drying. Most finishes will dry too fast in high temperatures (over 27C) and humidity below 30% or when air flows directly across the surface. Fast drying can cause brush, roller, or applicator marks because the finishing material will not have time to flow and level. As a preventative measure, turn on air conditioning to cool the area to about 27C or less, and then turn off before finishing, Apply finish early in the day, and keep sunlight off the floor (cover windows).

Wrinkling, Alligatoring, or Blistering. These can result from bottom coats not dry enough to accept a second coat, or a top coat solvents eating into weaker or uncured bottom coats. Wrinkling will result as blisters covering a large area of the floor, while alligatoring is very heavy wrinkling resulting when the top coat not only eats into the bottom coat, but actually lifts it from the wood or the floor stain. Prevention requires that stains and seal coats penetrate and adhere, and that all coats have sufficient air circulation and time to thoroughly dry.

Orange Peeling. The finish resembles the skin of an orange, resulting from the top coat setting too fast on the surface while taking longer to cure beneath. As the bottom dries very slowly, the finish surface begins to dimple from the shrinkage. Keeping air flow off a wet surface can prevent this, but it can also be caused by a cold floor.

Bubbles and Craters. These can by caused by air, solvents, or water coming through the surface after the finish has started to set, evidence of too-fast dry time. Bubbles are caused by air or solvent passing through the film; sometimes they cause pinholes when they burst, Craters are ridges left when bubbles break, and the surface finish does not lay back down. Prevention involves adjustment of temperature and air flow, allowing sufficient drying time for solvent release.

Separation of finishes in Spots or Along Cracks. Bare spots are evident. They come from contamination (wax of oils usually) on the surface and/or in between the cracks, and this contamination makes the finish crawl away. Wiping spots with lacquer thinner and recoating is often the solution. Delamination is evidenced by coats of finish separating from each other. This can be the result of failure to abrade between coats or the presence of contaminants such as wax that were not fully removed before applying the finish.

August 2012

The Bona Hardwood Floor Care System includes everything needed for easy and safe cleaning of hardwood floors on a professional level. The Bona Pro Series Hardwood Floor Care System is recommended for all types of unwaxed, residential and commercial polyurethane finished wood floors and pre-finished, aluminum-oxide floors. Leaves no dulling residue and is safe for wood. Includes:

Bona Traffic Anti-Slip Satin combines the legendary durability of Bona Traffic with slip resistant properties that meet the ADA recommendation for accessible routes and ramps according to ASTM 2047. It also meets the German Industrial Norm DIN 51 130 with a rating of R10. This German standard measures a product’s ability to provide slip resistance to improve safety in public and workplaces. This product has a sheen level of 25 at 60° and will use the same hardener as regular Bona Traffic

Reconditioned by Bona, includes a one year warrantee. The Bona Belt’s innovations include a compact chassis for easy maneuvering with increased power efficiency with the new Poly-V drive belt. Special transport wheels provide protection and convenience during transportation.

The Bona® DCS® Buffer’s technologically-advanced design is engineered for performance, convenience, durability, unequaled power, superb balance and superior dust pick-up.

The low deck design combined with the Illuminator adjustable light make working in hard-to-reach placeseasier than ever. When operated with a vacuum the DCS® Buffer is virtually dust free, meaning healthier working conditions for you, and better finish results leading to complete satisfaction of your customers.

Innovative vacuum chamber for superior dust pick-up, low deck height for access to toe kicks and other hard-to-reach places and adjustable illuminating height.

Wholesale Only to Professional Flooring Contractors

COLUMBIA INDUSTRIAL SUPPLIES

831 Shamrock Street, Victoria V8X 2V1; (250) 475-2295; (800) 606-2295; Fax (250) 415-2112;

columbiaindustrialsupplies@shaw.ca Web: columbiaindustrialsupplies.com

#1135

December 14, 2011

Bona Products: Freeze-Thaw Stability

To: All Bona Distributors

Due to adverse weather conditions that can occur during the winter months, Bona US has tested all

products for their freeze-thaw stability. Each product group is described individually below.

Solvent-Based Products

The solvent-based products may thicken but will never fully freeze. Allow product to warm to room

temperature and place into stock as normal.

: Bona’s solvent-based products are freeze-thaw stable in all conditions.Floor Care Products (Cleaners)

to warm to room temperature and place into stock as normal.

: Bona’s floor care products are freeze-thaw stable. Allow productsFiller and Adhesives

Allow products to warm to room temperature and place into stock as normal.

: Bona’s Pacific Filler and Adhesives are freeze-thaw stable in all conditions.Waterborne Products

waterborne products can have a stability issue if they do not freeze completely and are

bounced/vibrated/shaken either during shipping or use. The partially frozen product contains ice

crystals which are very “sharp” and can cause the polymer in the product to become unstable.

Lower VOC products are more susceptible to this situation due to the lower amount of solvent in

the product. Determining if a product was only partially frozen during shipment is difficult, so one

must inspect the product to determine if it is acceptable for use.

Once the product has been brought to room temperature, sample one bottle of each finish

(irrespective of sheen). Pour the product into a clean container. If there is a stability issue, clumps of

product (similar to “cottage cheese”) will be present. If the product pours easily with no large

coagulations, the product is fine and can be place into stock as normal.

Best regards,

Todd Weyhmiller – Strategic Business Manager – Professional

: While all Bona’s waterborne products are tested and are freeze-thaw stable,Bona US

2550 South Parker Road, Suite 600

Aurora, CO 800141622

303/3711411

800/8725515

FAX 303/3716958

www.bona.com